Chemical Sensing

General Chemical Sensing

Electrochemical sensors are powerful and versatile tools that can detect a wide range of analytes in a variety of applications. At CMW, our work revolves around two main areas of focus:

Biochemical Measurements

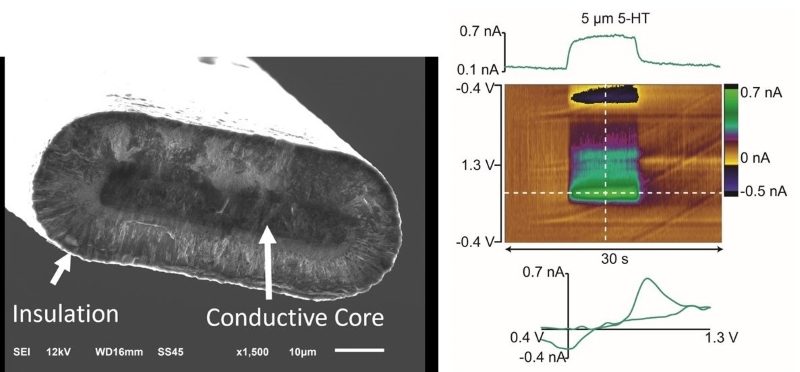

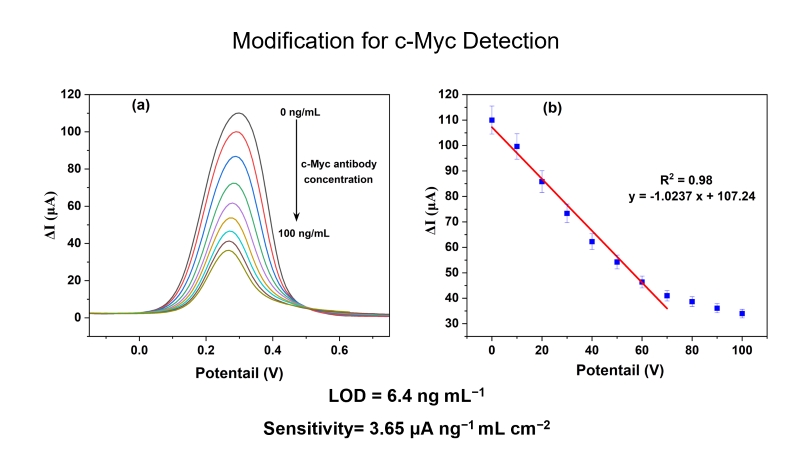

We specialize in the detection of bio electroactive metabolites like dopamine and serotonin using fast-scan cyclic voltammetry (FSCV), which allows for high-resolution, real-time monitoring. For non-electroactive metabolites and biomarkers, we use surface modifications and biomolecule attachment to develop both label-free and sandwich-type electrochemical immunoassays. By immobilizing bio-recognition elements or using electroactive tags, we enable selective, sensitive detection across diverse sample types.

Environmental Measurements

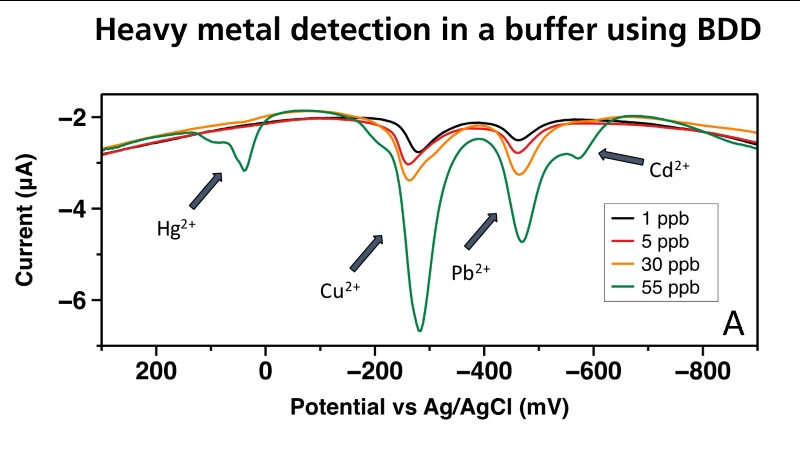

Our sensors detect various electrochemically active species, including heavy metals like Pb²⁺, Cd²⁺, Cu²⁺, and Hg²⁺. In addition, we use surface modification techniques to create pH sensors. Furthermore, we use electrochemical advanced oxidation processes (EAOPs) to release and detect bound contaminants, providing a deeper understanding of environmental systems.

Diamond Sensors

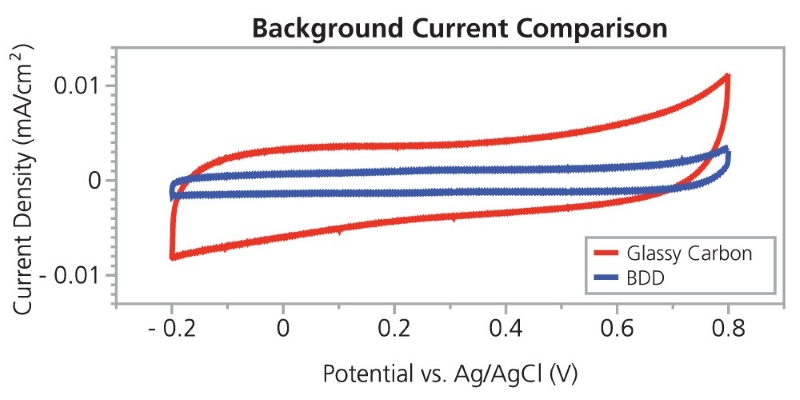

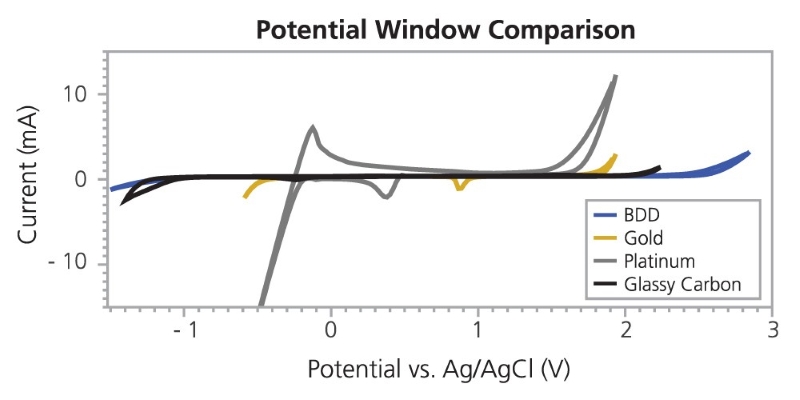

Boron-doped diamond (BDD) is a unique and robust electrode material with a large potential window in aqueous solution and low background current. With its resistance to electrochemical fouling and wider potential window with a lower background current, BDD material is an attractive surface for electrochemical analysis experiments. It is a green and renewable surface through acid cleaning and activation for repeated experiments.

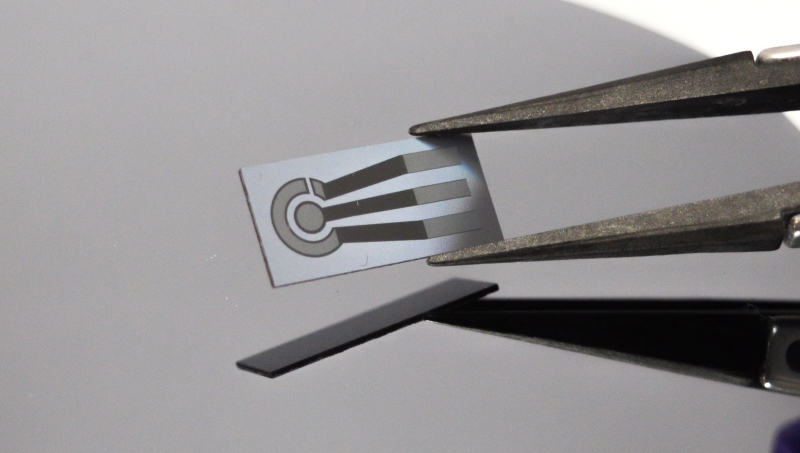

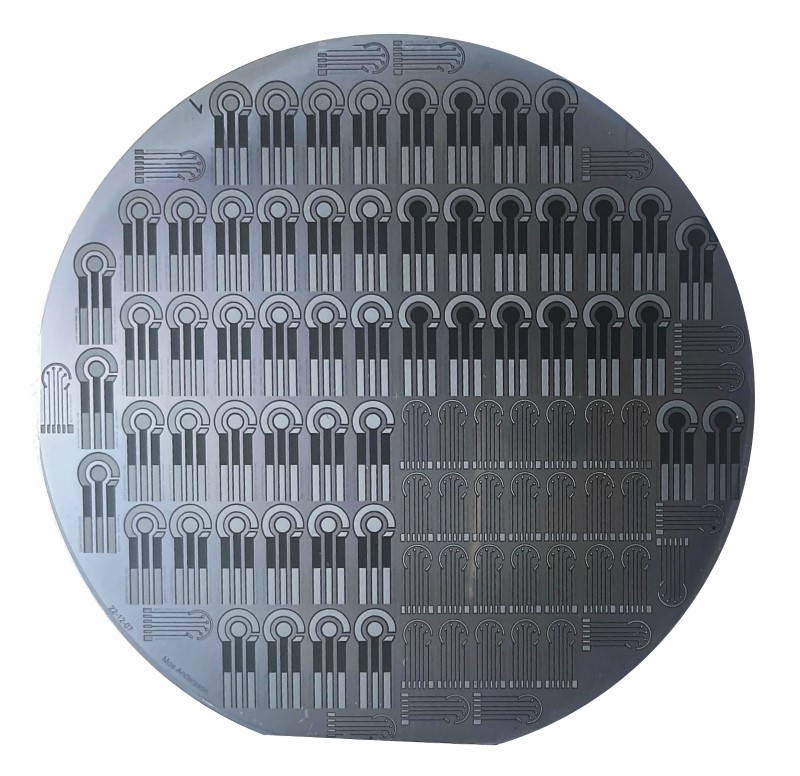

We developed a large portfolio of boron-doped diamond electrodes and materials targeting a broad range of markets, including biotechnology, environmental, and health. The available portfolio is offered to collaborators and project partners to further advance the technology and develop products. These electrodes are made by growing in-house CVD polycrystalline diamond, and through wafer processing techniques such as lithography and reactive ion etching, we can structure these into a variety of 2D shapes and sizes to meet your needs.

With a lower capacitive background current and wider potential window to other competing electrode materials, such as glassy carbon (GC), our BDD electrodes can be used for electroanalytical measurements with ease. BDD has advantages over a variety of electrode materials, including GC because of the flat background, enabling a broader range of measurements.

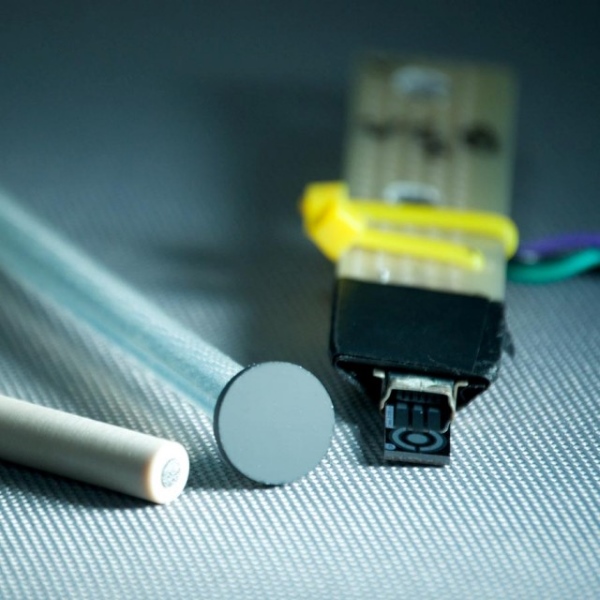

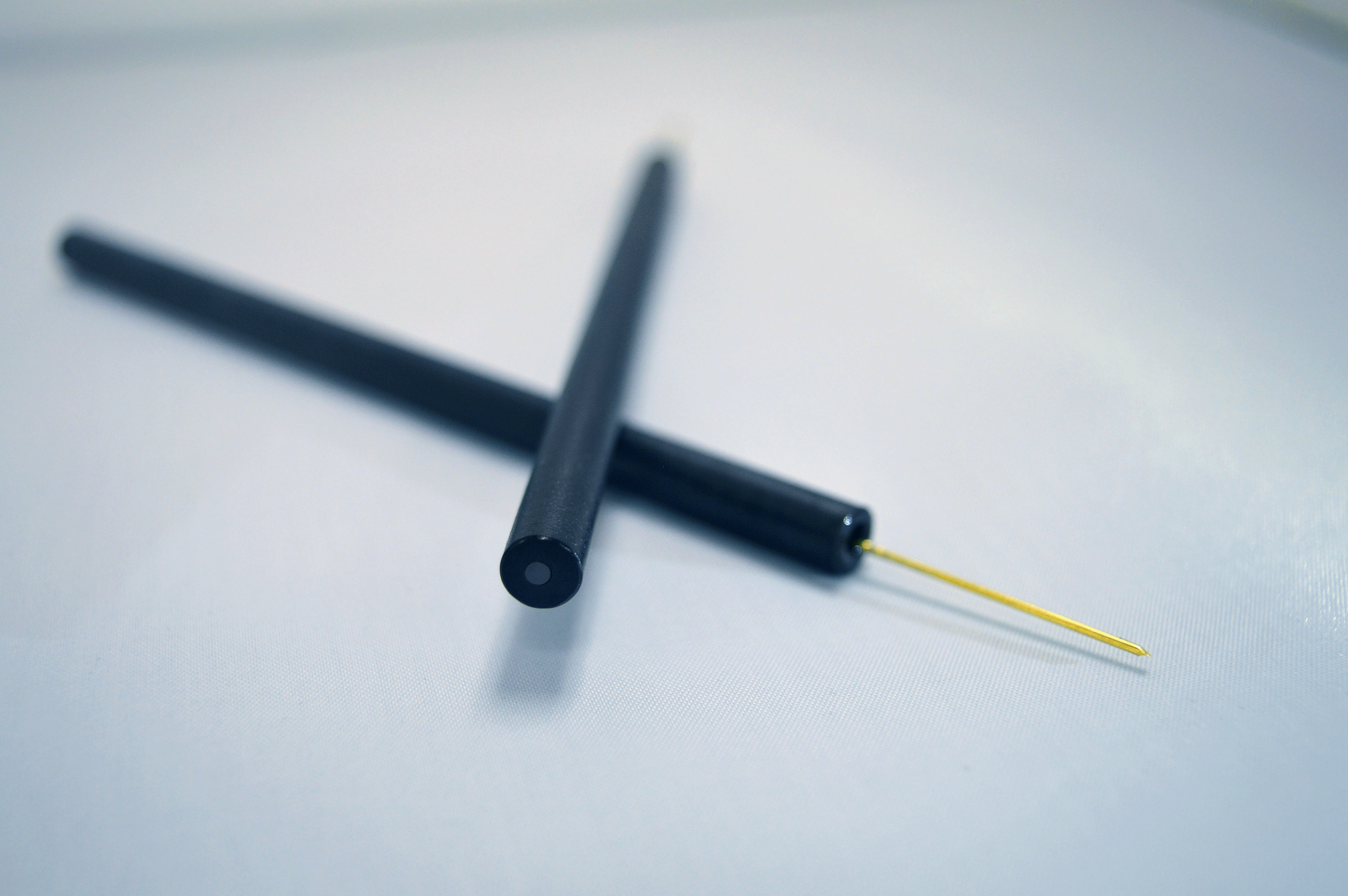

Disk Electrodes

2mm BDD electrode packaged into a PEEK housing

2mm BDD electrode packaged into a PEEK housingBDD disk electrodes offer superior electrochemical performance to other commercially available electrodes. Standard electrodes embed a 2mm polished BDD disk in a 6cm long x 6mm outer diameter PEEK housing. Custom orders with other chemical resistant housings, including PTFE, are possible.

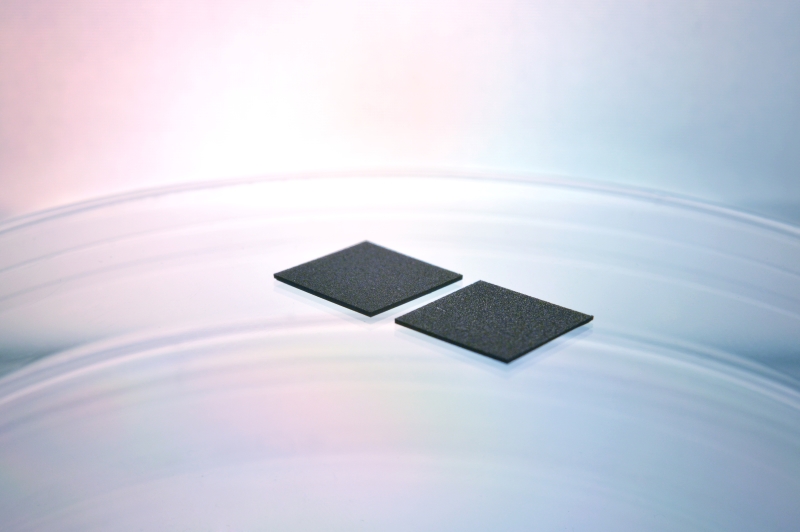

Diamond Plates

10 x 10 mm BDD freestanding plate electrodes

10 x 10 mm BDD freestanding plate electrodesBoth BDD grown to varying thicknesses on either conductive or insulating silicon as well as free-standing BDD plates are available for a variety of applications. These plates can be modified to fit specific experimental needs. BDD plates exhibit high electrical conductivity that is maintained at elevated temperatures, excellent mechanical and chemical rigidity, and long-lifetime. BDD on silicon can be grown as thick as 40 µm. Freestanding BDD plates are grown to 350 μm thick. Both materials are as-grown and unpolished. The material is typically offered in 10 mm x 10 mm geometries, but smaller and larger geometries can be accommodated through laser dicing.

Boron-Doped Diamond Optically Transparent Electrodes

BDD OTE film on a quartz substrate

BDD OTE film on a quartz substrateCombining the advantage of rugged BDD material with optical transparency, BDD optically transparent electrodes (OTEs) are excellent tools for spectroelectrochemical measurements. Applications range from the general study of redox chemistry (inorganic, organic, biological molecules) to spectroelectrochemical sensing where excellent sensitivity and selectivity can be obtained.

The BDD films are grown on quartz substrates and exhibit a wide range of optical transparency. Measurements can be made below 300 nm, a quality certain OTE materials can not achieve. The optical and electronic properties can be altered depending on experimental requirements; a more conductive film will be less optically transparent, while a more optically transparent film will be less conductive. Custom dimensions including microfabrication can be accommodated to fit a specific geometry.

Custom Electrode Fabrication Capabilities

Boron-doped diamond (BDD) fabrication capabilities range from diamond growth via post-growth fabrication to assembly and material evaluation. BDD films can be applied to a variety of substrate materials and geometries ranging from small (micron ) to large (4” Si wafer) substrates. Post diamond growth capabilities include polishing, photolithography, etching, metallization, and laser-cutting.

Diamond is grown on a variety of substrates, including but not limited to certain metals (including expanded metal mesh), quartz, pyrex, silicon, and polycrystalline diamond. With the application and product in mind, substrates are carefully evaluated and individually pre-treated for optimized diamond growth and resulting diamond materials. In-house clean room microfabrication processes allow for 4” diameter wafer processing including PVD (metallization) and PE-CVD (SiO2 ) thin film deposition, photolithography and plasma etching.

Diamond lapping, polishing and laser cutting complement the Center's capabilities, striving towards a one-stop solutions provider for BDD electrode development and prototypes.

Custom Instrumentation and Setup

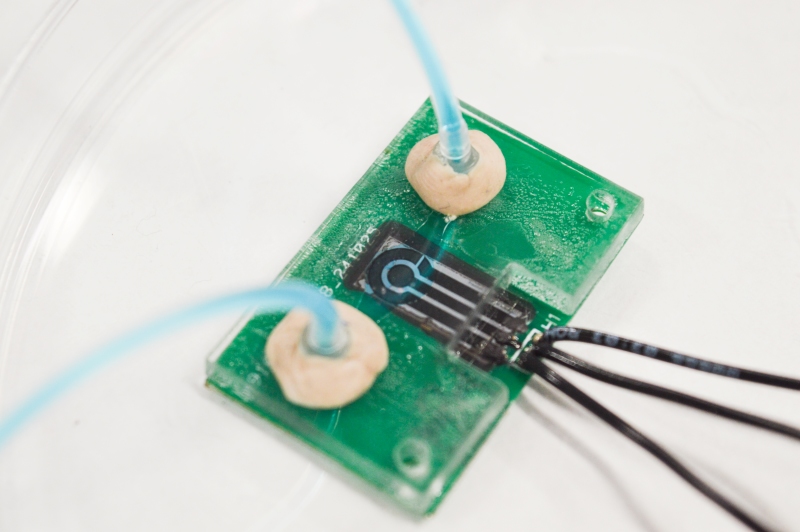

Often electrodes and instrumentation need to be fabricated custom for the experimental setup and needs. The in-house fabrication equipment provides great flexibility and enables us to design tailor the measurement needs. Through custom microcontroller programing, to electronics design, CMW has built microcontroller based potentiostats utilizing python interface software. CMW also specializes in providing wholistic solutions, such as designing electrode interfaces with microfluidics and instrumentation.

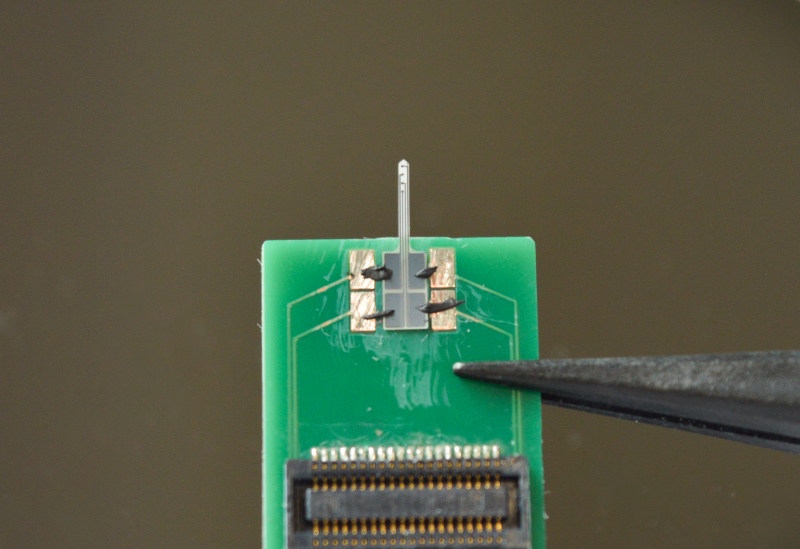

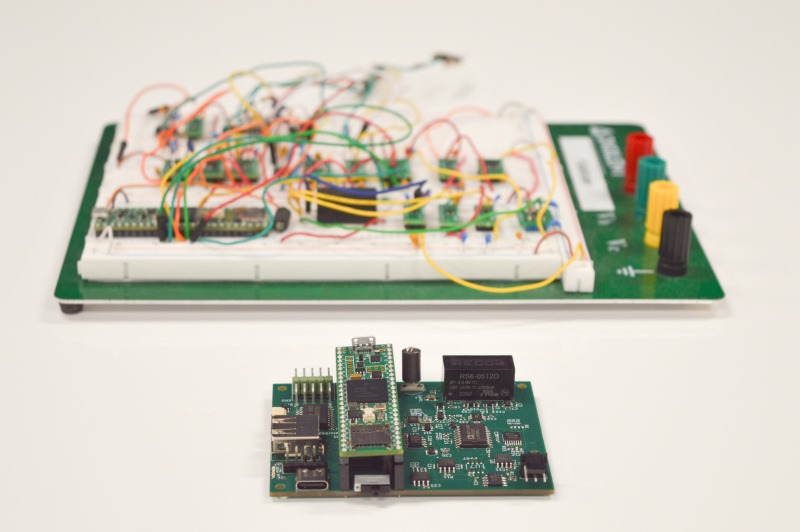

- Design of a microcontroller potentiostat, and iterating from bread board to printed circuit board for real-time heavy metal measurements.

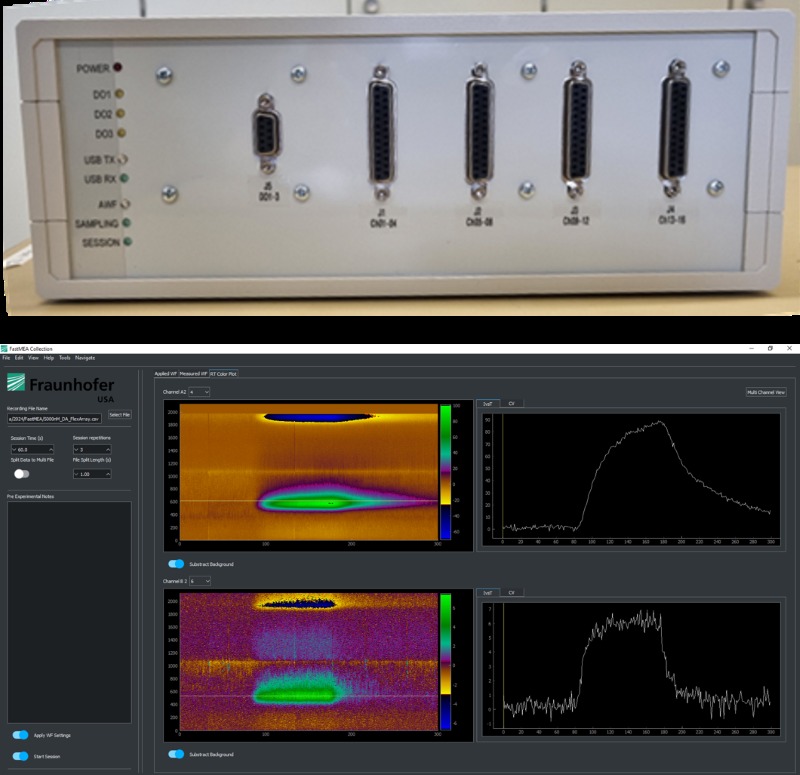

- In collaboration with Fraunhofer Institute for Microelectronic Circuits and Systems, and Fraunhofer USA Center Mid-Atlantic, we developed a 16-channel Fast-scan cyclic voltammetry recording system for high-speed electrochemistry to measure dopamine on our diamond microelectrode arrays.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW