Coating Development

Functional Thin Films

Functional thin films provide new surface characteristics for materials without changing their bulk properties. This can include wear and friction, self-cleaning, conducting, insulating or piezoelectric, corrosion protection, and barrier properties. Thin film materials include metals, non-metals and oxides, and nitrides thereof.

The technology spectrum covers conventional and advanced magnetron sputtering, ion beam deposition and arc evaporation techniques from laboratory scale, prototype to pilot manufacturing scale.

Optical and Optoelectronic Coatings

With its range of coating technologies and optical characterization tools, CMW enables the development of optical coatings for various substrate materials, including polymers, glass, and minerals. Most applications target refractive index matching to achieve selective wavelength filtering and specific or broadband anti-reflective film properties. Other focus areas are ultra-thin metal and transparent conductive oxide coatings for Low-E or optical sensing applications.

Analysis and Characterization

Applied analysis of synthesized coatings and thin films is critical to ensure product performance. Fraunhofer USA CMW offers a wide array of analysis and characterization techniques. Besides standard analysis options such as

- Microscopy (optical, stereo, SEM, digital)

- Optical Spectroscopy (UV-Vis-NIR, FTIR)

- X-ray-based (XPS, XRD, SEM/EDS)

- Tribology

- Electrochemical methods

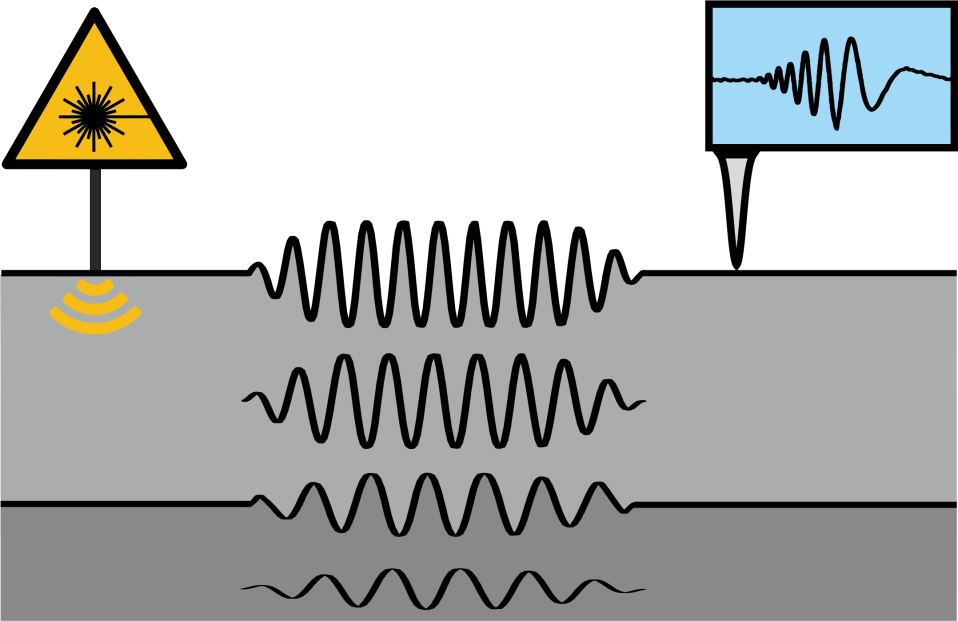

Fraunhofer USA CMW is proud to offer a unique laser acoustic wave spectroscopy system (LAwave®) used for fast and non-destructive characterization of coatings and surfaces. Together with our partners - Fraunhofer Institute for Material and Beam Technology (IWS) and Fraunhofer USA Center for Manufacturing Innovation (CMI) - we offer system sales and support for the U.S. market.

Download material here:

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW