Thermal Management

Direct Diamond Epitaxy on Devices for Thermal Integration

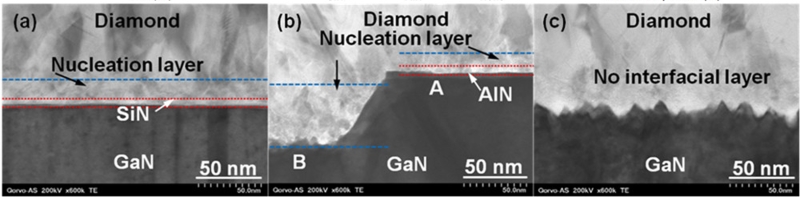

Fraunhofer USA CMW has developed polycrystalline synthesis processes that can be used for direct overgrowth of SiC, GaN and AlN devices to provide optimized cooling performances.

Utilization of optimized interlayers minimizes the low thermal conductive nucleation layer at the interface to the device. This, minimizes thermal boundary resistance and improves cooling capacity of the entire system. Fraunhofer USA CMW was able to demonstrate state-of-the art metrics by deploying a SiN interlayer, i.e. effective thermal boundary resistance of ~ 6.5 m2K/GW. This synthesis technology can be deployed at wafer-scale (currently up to 8-inches) and for controlled infill of fin structures with diamond.

See more: Diamond Electronics

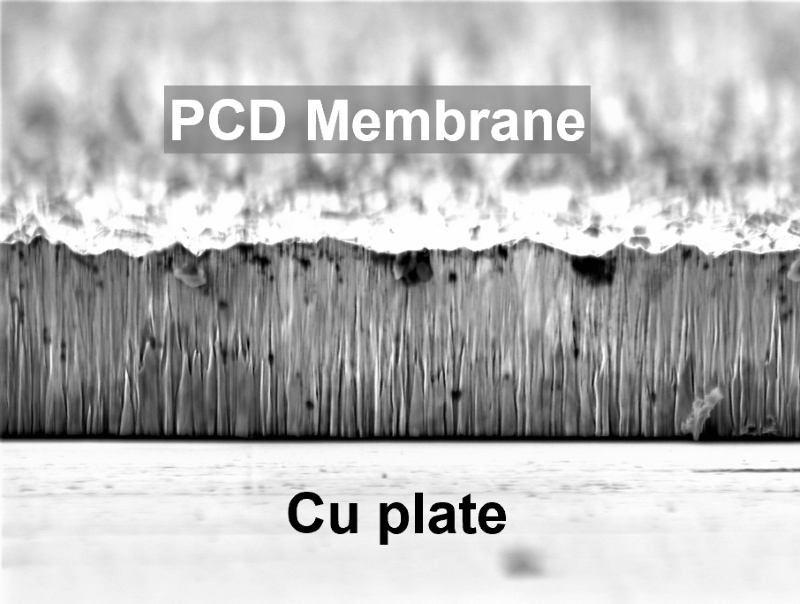

Diamond Membranes

Fraunhofer USA CMW has developed the polycrystalline diamond nanomembrane technology to serve as a novel solution for novel diamond thermal integration. CMW’s nanomembranes can be directly integrated with existing systems as retrofits, or developed from the ground up. The advanced fabrication technologies at CMW allow for removal of any low thermally conductive diamond material to create membrane with thermal conductivity on the order of 1200 W/mK (comparable to single crystalline material), while also being only a few microns (µm) thick. These nanomembranes are either directly integrated and used as direct heat spreader, or via device stack integration to serve as thermal interface material. These nanomembranes can be seamlessly integrated with other semiconductor materials (Si, SiC, GaN), ceramics (SiO2, Al2O3), polymer, but also copper.

See more: Diamond Membranes

Diamond-Copper Composite Materials

Fraunhofer USA CMW offers a unique diamond-copper composite material. Thermal conductivity of this material can be on the order of 800 – 1000 W/mK, double that of pure copper. All while possessing density and electrical conductivity values of traditional copper heatsink material.

Leveraging additive manufacturing techniques for fabrication, this composite material can be easily fabricated into complex 3D heat spreader shapes that also contain fins and internal cooling channels that would be hard to or impossible to achieve using traditional machining.

See more: Additive Manufacturing

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW