Polishing and Surface Treatment

Chemical Mechanical Polishing (CMP)

We are advancing the state of the art in diamond CMP, offering industry partners expertise in both process development and equipment design. Our CMP capabilities routinely achieve sub-nanometer roughness over large area diamond wafers, including wafers with thin epilayers (i.e. 1 – 2 micron) without inducing taper or breakthrough into the underlying substrate. This level of precision is critical for enabling next-generation technologies in high-frequency, heterojunction, and other electronics applications. As the demand for ultrasmooth diamond surfaces grows, we are proud to support the expanding diamond electronics ecosystem with best-in-class CMP solutions.

Surface Functionalization

Fraunhofer USA CMW can perform a wide range of surface functionalization, including hydrogen, oxygen and nitrogen, as well as re-application thereof on previously terminated substrates. A broad range of tools is utilized using either plasma- or non-plasma tools to be suitable for a range of substrates from diamond, silicon, ceramics, as well as polymers.

Quantification of surface functionalization can be performed using a wide range of analytical tools, such as XPS and contact angle measurements.

Deep Reactive Etching

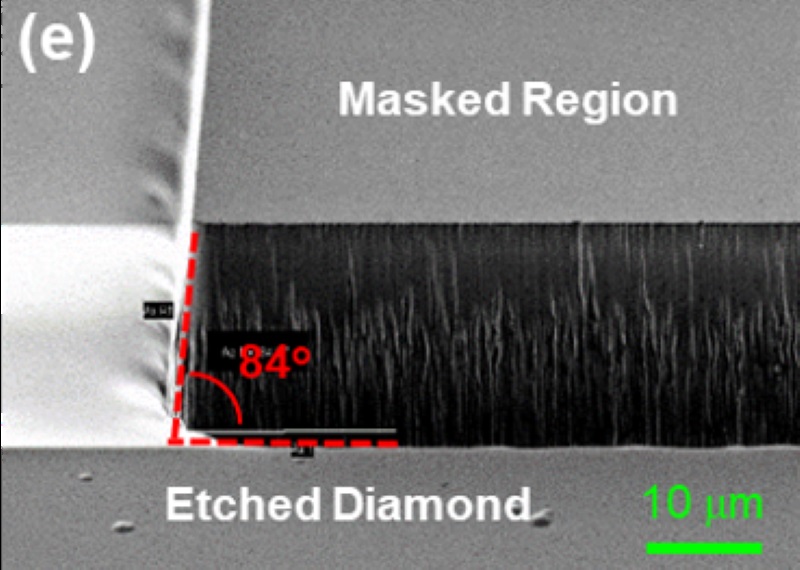

The combination of its physical hardness, chemical inertness, high thermal conductivity and limited thermal expansion make the task of dry etching and structuring of diamond uniquely challenging compared to other semiconductor materials. Etch solutions typically suffer from low etch rates and aspect ratios, and frequent and premature etch mask failure. Especially the latter can be catastrophic for device fabrication. We developed a thermally matched bilayer etch mask that is capable of upholding the unique challenges during diamond etching. Use of the etch mask allowed for diamond etching with etch selectivity exceeding 150:1.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW