Amorphous Carbon

Diamor®/Tetrahedral Amorphous Carbon (ta-C)

Fraunhofer USA Center Midwest (CMW) centers its coating development on Diamor®, scientifically referred to as tetrahedral amorphous carbon (ta-C). It is not only renowned for its exceptional hardness but also exhibits a low coefficient of friction and chemical inertness. These ta-C coatings with sp3 contents of up to 80% can be achieved at rates of about 2 µm/min at room temperature – a key technological advantage – by a unique coating production tool, the so-called Laser-Arc®.

Diamond-like Carbons (DLCs)

The CMW expertise and coating technology covers the entire spectrum of amorphous carbons according to ISO 20523:2017 from hydrogen-free to hydrogenated DLCs and modifications with other solid or gaseous elements. This allows the material properties to be tailored towards specific application requirements such as optical transparency, surface energy, toughness or elasticity, electrical conductivity, thermal stability and more.

Modified Amorphous Carbon

CMW develops next-generation amorphous carbon materials by tailoring their structure beyond conventional sp³ bonding. Through the controlled incorporation of elements such as nitrogen, fluorine, and a range of metal and non-metal dopants, CMW fine-tunes key material properties - electrical, mechanical, optical, thermal, and chemical - for demanding applications.

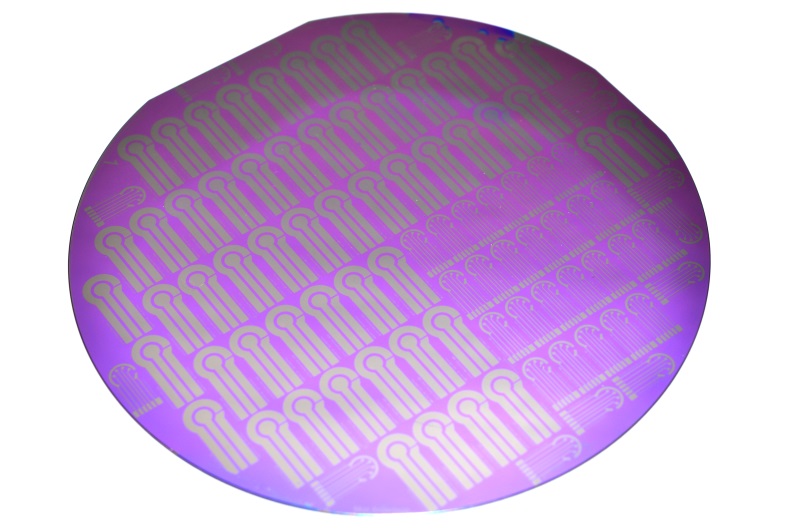

A current focus is nitrogen-incorporated tetrahedral amorphous carbon (ta-C:N) for scalable and low-temperature processing electrochemical sensors, expanding established capabilities in boron-doped diamond (BDD) electrode technologies.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW