Diamond Growth AI

Segmentation Algorithms

Two AI algorithms are being used to segment input images into machine readable labels to (i) identify geometric features of the diamond and growth chamber, and (ii) identifies various crystal defects and undesirable growth patterns that are detrimental to the final diamond wafer.

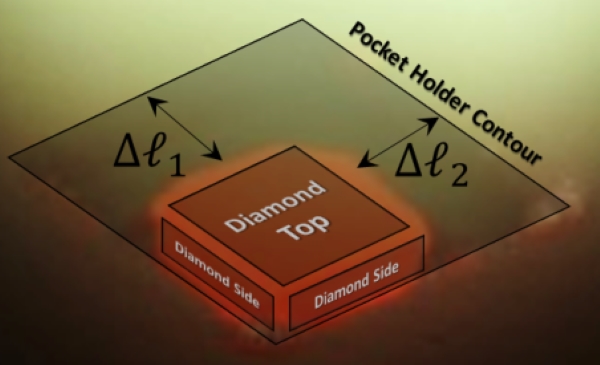

The geometric segmentation algorithm labels and measuring the corresponding image regions of interest belonging to the top and sides of the diamond, as well as the recessed pocket holder used for the diamond growth.

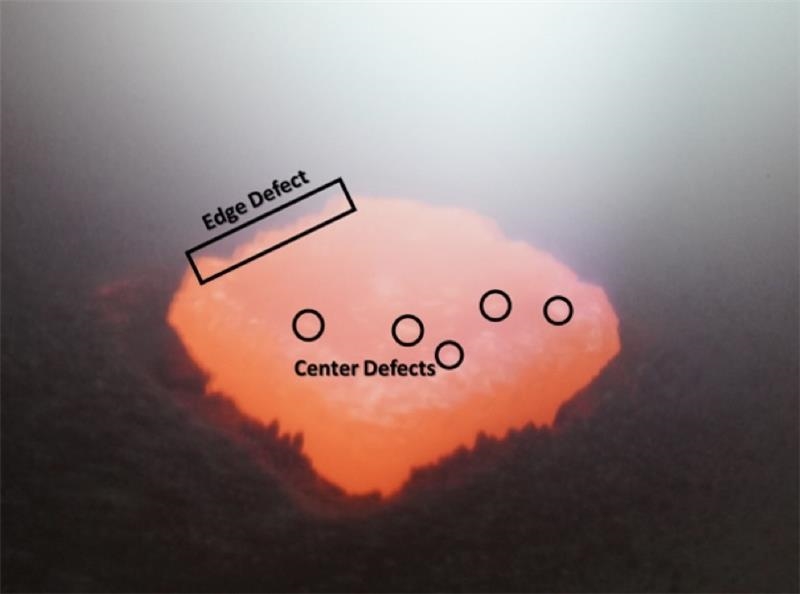

The defect detection algorithm labels center defects, which are predominantly crystalline defect clusters, and edge defects, which are competing (100), (110) and (111) crystalline growth directions. Further, the defect detection algorithm can also identify and classify parasitic polycrystalline diamond (PCD) growth at the diamond itself, as well as on the holder. Extensive PCD growth on the holder has a detrimental impact on the growth of the SCD wafer itself.

Prediction Algorithm

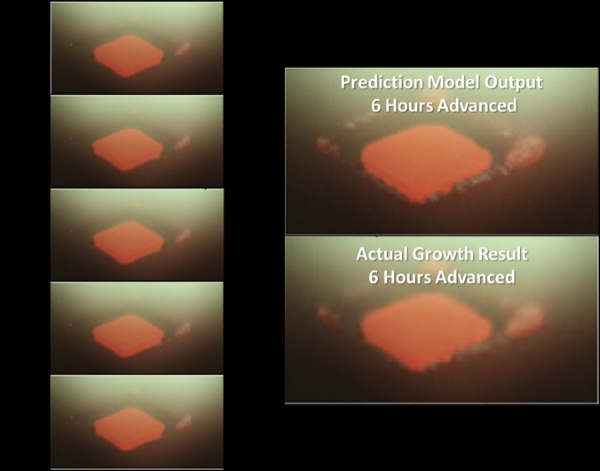

The growth state prediction algorithm uses a time series of labels from the geometric segmentation and the defect detection algorithms and reactor process conditions to predict future growth states. By using input series of 40 minutes of diamond growth it was possible to predict the growth state of diamond wafers up to 20 hours into the future. This prediction included accurate prediction that of parasitic PCD growth.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW