Plasma Enhanced Materials Processing

Plasma Activation

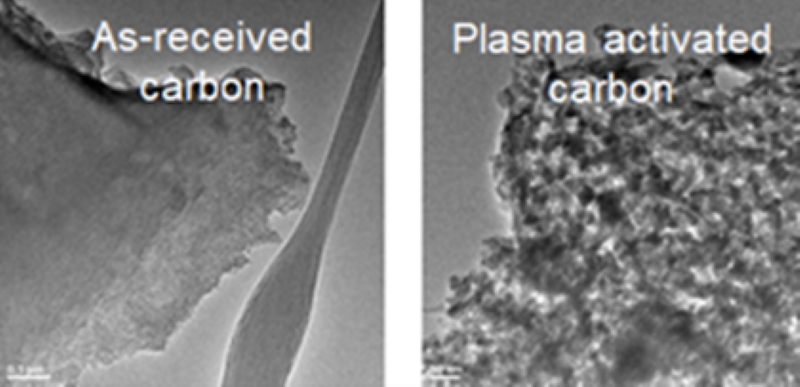

Conventional carbon activation methods typically involve high-temperature chemical treatments exceeding 900°C for more than two hours, followed by extensive washing and drying. This energy-intensive and time-consuming process has posed a significant barrier to the commercialization of carbon materials such as biochar for advanced applications.

CMW has developed a patented, highly efficient plasma activation system that overcomes these limitations. This innovative approach enables dynamic activation of biochar in less than 10 minutes without the need for external heating. Plasma activation not only enhances the surface functional groups of biochar but also promotes the formation of micro- and mesopores, significantly improving its adsorption performance.

Overall, this process is more energy-efficient, and more environmentally friendly compared to conventional chemical activation methods.

Energy Storage Materials

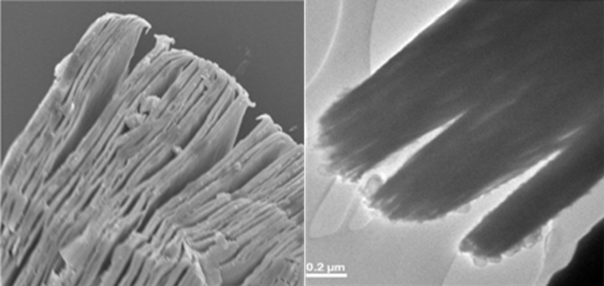

Carbon-based materials are excellent candidates for electrode applications in energy storage devices such as batteries and supercapacitors, due to their robust pore structures and high surface areas. Their electrochemical performance can be significantly enhanced through targeted modifications, including surface functionalization and pore structure optimization.

CMW utilizes advanced plasma technologies to tailor the morphology of carbon-based materials for energy storage applications. For instance, we have successfully employed plasma-assisted exfoliation of graphite oxide modified MXene, which exhibits outstanding capacitance performance when used as an electrode material for supercapacitors.Our group can help industry and research labs to design highly efficient DC sputtering magnetrons and ion sources.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW