Overview

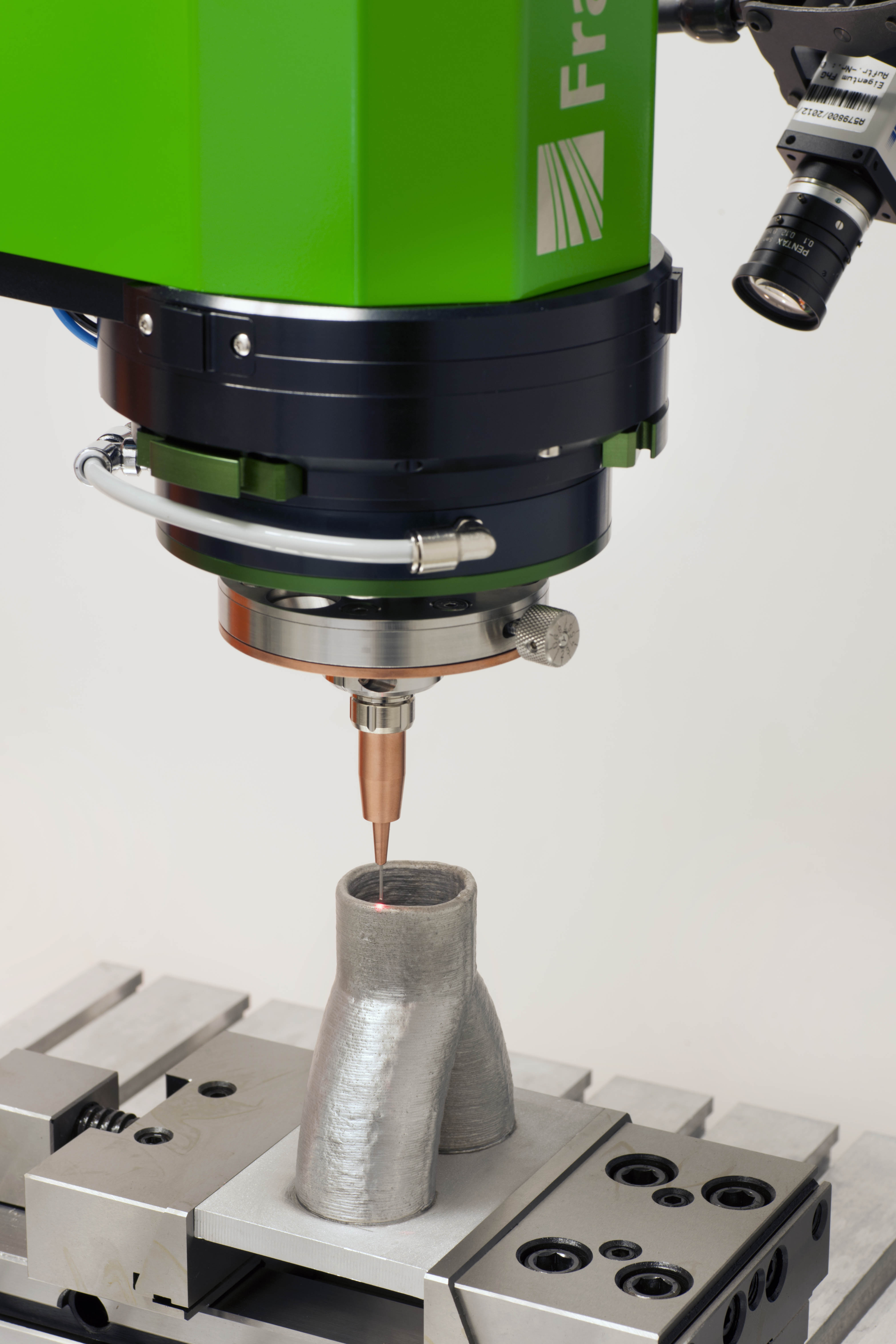

Fraunhofer is one of the pioneers in the growing field of additive manufacturing. Our process expertise includes the developement of a range of state of the art powder delivery nozzles which enable precise placement of the metallic powder material relative to the laser beam focus.

Our proprietary process monitoring and control technology and CAM to Path tool path generation software enable us to generate complex tool paths for build-up of high quality prototype components and for custom manufacturing.

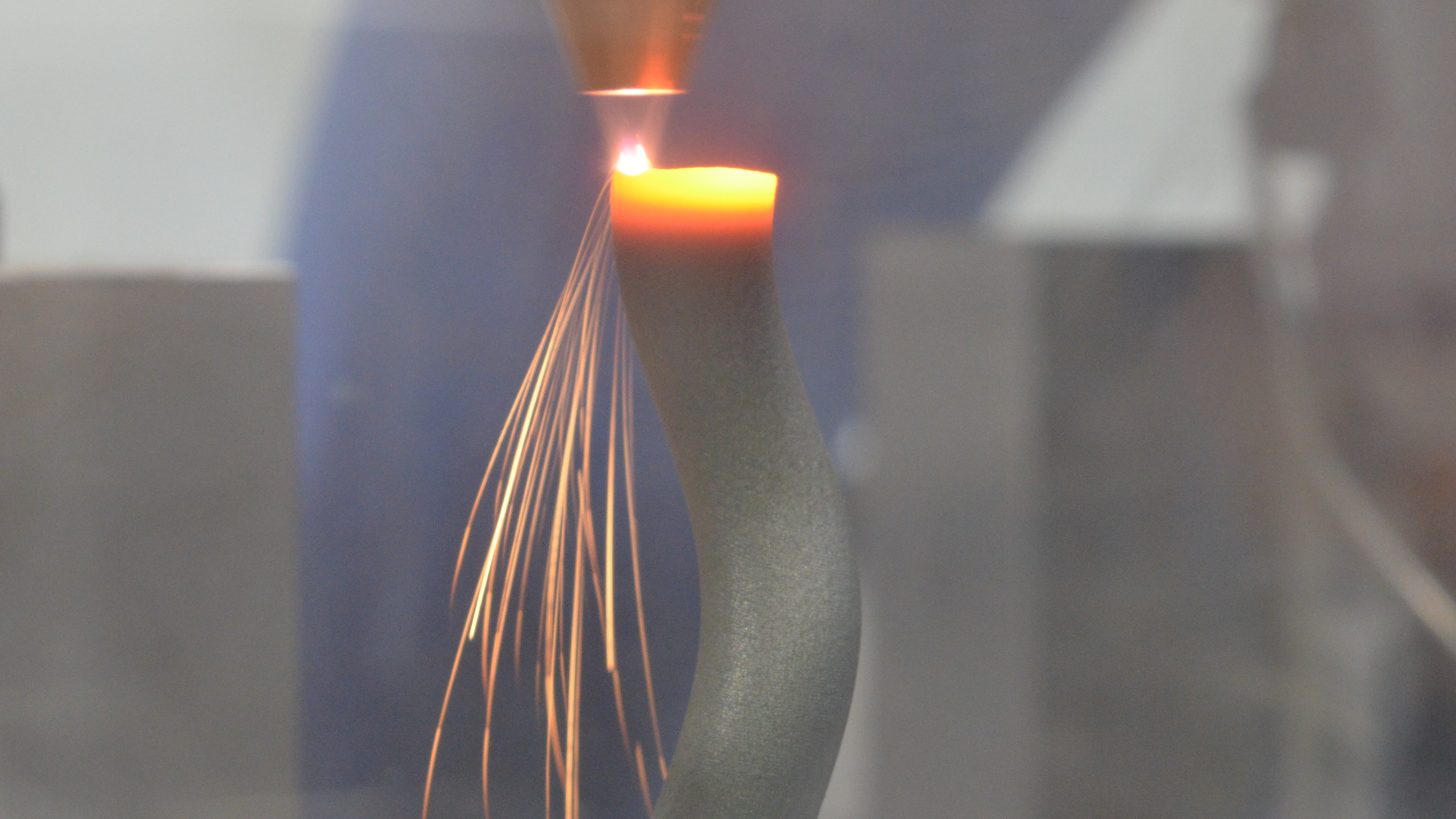

Our patented induction assisted powder deposition technology enables improved deposition rates and deposit quality even on crack sensitive super alloy materials.

Advantages

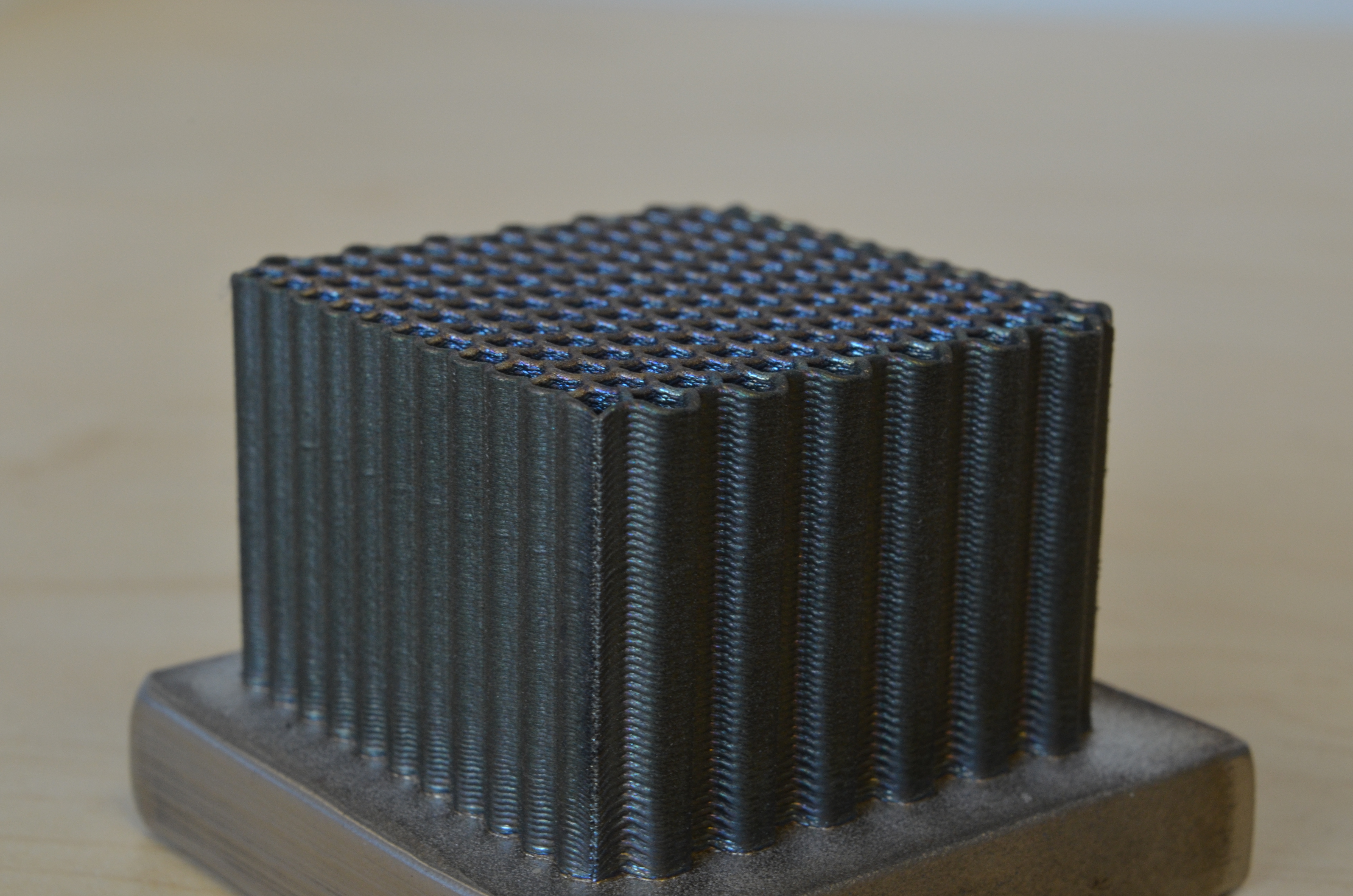

- Low heat input / distortion

- Precise control of microstructure

- Minimal post machining requirements

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW