Filament Development

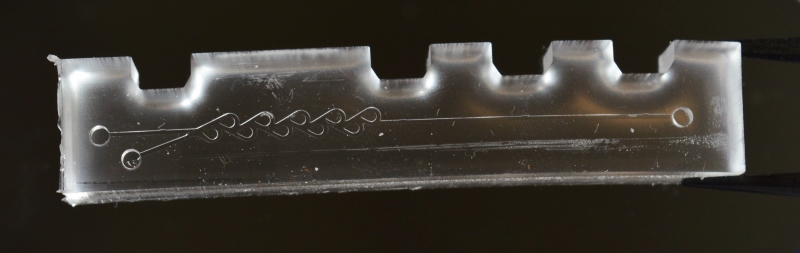

Research interests at Fraunhofer USA CMW include multi-material printing and filament development for printing complex metals and ceramics as well as materials for medical applications. Multi-material printing is achieved by utilizing multiple print heads to lay down material simultaneously. Our core areas focus on either compounding composite materials such as carbon fiber, or nanoparticles into a polymer matrix, and using this feedstock for additive manufacturing into unique and complex geometries. We achieve this by compounding photoresin with nanoparticles followed by photopolymerization printing and polymer compounding with extrusion-based printing.

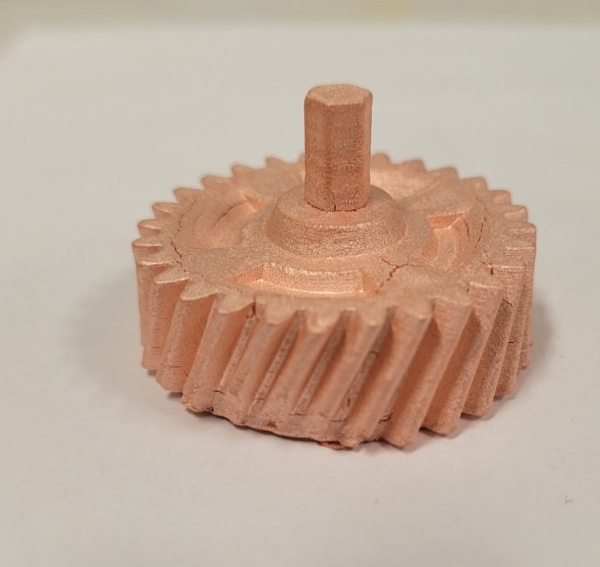

The second core area focuses on metal and ceramic additive manufacturing through a sintering-based approach. By loading a polymer matrix with a high-volume percentage (45% volume, or 90% mass) of metal or ceramic powder, this compounded material can be additively manufactured into complex geometries using standard filament extrusion. After printing, first a solvent and second a thermal debinding process removes the polymer. Then the parts are densified at the respective sintering temperatures (1000-1500 ⁰C) yielding a solid, dense metal or ceramic part. This type of structuring, like metal injection molding, leverages small batch prototyping and prototype production for both metal and ceramic designed parts. Parts can be completely solid or have a varying infill percentage to tune the mechanical properties for intended use cases.

In house, we have the capability to compound polymers with the metal, and either produce pellets for metal injection molding, pellet additive manufacturing or extrude into filaments for fused filament fabrication. These materials can not only be processed individually, but also as a multi-material structure through a dual nozzle system.

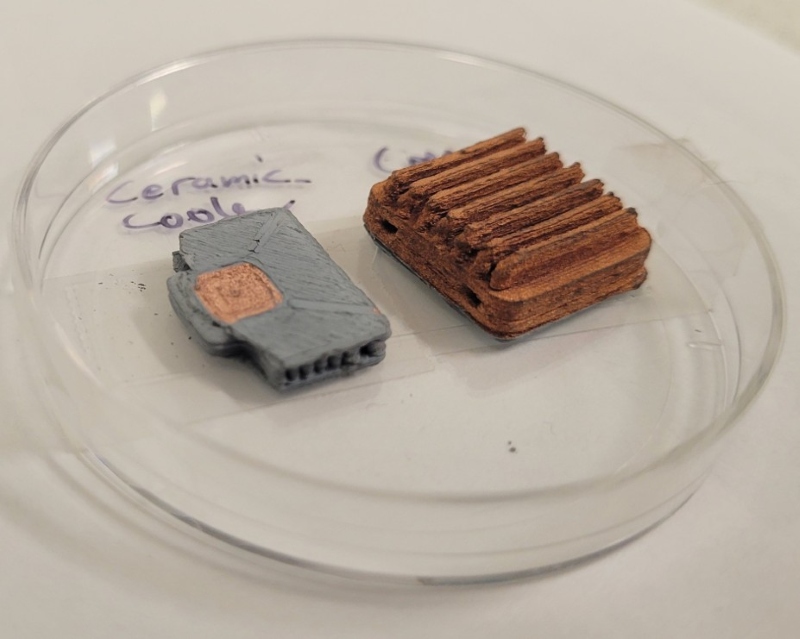

Multi-component thermal transfer devices:

Copper and ceramic structures are desired for thermal heat transfer devices. Classically these are individually fabricated and assembled but have areas of thermal loss. Through a collaborative project with Fraunhofer Institute for Manufacturing Technology and Advanced Materials we developed a mechanism to both gel cast and fused filament fabricate copper, copper-diamond and a low temperature modified alumina ceramic to form multicomponent structures for thermal transfer devices. These co-printed and co-sintered devices leverage material properties to modify the ceramic densification temperatures and thermal manipulation to overcome thermal expansion mismatches for complex geometries. These multi-material structures can be used for a range of applications, encompassing biomedical, automotive, aerospace, electronics and thermal applications.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW