Overview

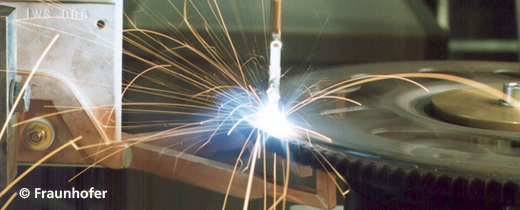

For difficult to weld and crack sensitive materials, Fraunhofer has developed induction assisted laser welding technology which can be used to pre and post heat components in order to control the cooling rate of the weld in order to avoid the formation of brittle weld and HAZ microstructures. Fraunhofer has several patents in this field has susccessfully transferred this into industial production.

Advantages

- Crack prevention in high carbon equivalent materials

- Prevention of undesirable microstructure formation

- Reduction of transient stresses

- Increase of welding speed

- Localized and easily automated

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW