Overview

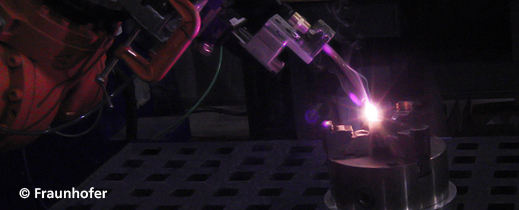

High quality brazing is also possible using laser technology.

Laser Brazing uses a lower melting point filler wire material which is melted by the laser beam to form a brazed joint with extremely high quality and surface appearance. Indeed automotive Class A quality finishes are possible with little or no after weld polishing.

Advantages

- High quality surface finish (Class A Automotive)

- Low heat input and less distortion compared to laser welding

- Joining of disimilar metals

- Less investment costs due to lower beam quality and laser power requirements

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW