Overview

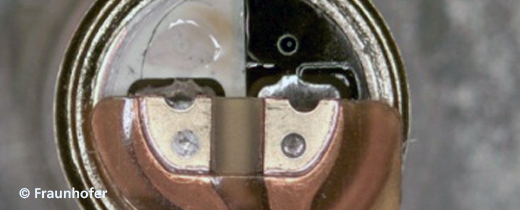

In laser soldering, the laser beam provides controlled heating of the solder material and joint area which causes solder to reflow and form the joint. Fraunhofer has suitable laser sources with small spot sizes (down to <0.1 mm) and can perform high quality soldering using lead based and lead-free solders. Tailored heat cycles by laser pulse shaping are available. Special laser soldering heads have been developed for custom power electronic board soldering.

Laser soldering is most suitable for joints that require soldering for:·

- Heat sensitive electronic parts that cannot be soldered in a reflow oven

- Sealed receptacles, such as, small SMD circuit boards

- Repair and service of electronic components

- Joining of fine wire bonds with diameter (<100 µm) replacing conventional silver-epoxy bonding

- Complex part geometry which restricts joint access with other conventional methods

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW